Thermoplastics

Our approach to working hand-in-hand with the industry and our customers to generate solutions that overcome their production challenges is behind the wide range of products we have developed for thermoplastics processing. Our portfolio is focused on the goal of increasing quality and productivity while minimizing any adverse impact on the environment, thus adding overall value to our customers’ bottom line.

We serve the thermoplastics industry through our Lusin® mould maintenance products and release agents as well as our Ultra Purge™ purging compounds.

Related

Ultra Purge™ 3615 Purging Compound

The Chem-Trend Ultra Purge™ 3615 purging compound is designed for fast residue free cleaning and easy screw pulls. Users benefit from considerably less scrap, more consistent process quality finally resulting in higher production efficiency.

Our R&D team is committed to deliver solutions that make your production process as efficient and simple as possible.

Chem-Trend’s experienced R&D team continuously works to develop advanced release agents, purging compounds, and mold maintenance products that allow thermoplastic processors to improve product quality, and reduce downtime and scrap rate.

To see our Germany-based facility and learn about our process, watch the video.

Driving force for manufacturing processes in e-mobility

The rise of electric vehicles (BEV, PHEV, HEV and eVTOL) is revolutionizing the automotive industry and presenting us with ever new challenges. For OEMs, this means increasingly stringent technical requirements and higher manufacturing costs, while maintaining efficiency, quality and cost effectiveness.

To Help You Go Green Without Seeing Red

As thermoplastics processes and materials become more complex and cost pressures increase, the need for high-efficiency purging compounds and mould maintenance products becomes even more crucial. We can help solve common challenges in the thermoplastics manufacturing process.

Ultra Purge™ Purging Compounds

Purge compounds are extremely important for modern thermoplastics processors, and the use of purging compounds that are designed specifically for operational processes and parameters can provide a significant competitive advantage. Eliminating carbon buildup in screw and barrel assemblies, as well as on die sets, has a significant impact on processing efficiency, scrap rates, die life, and equipment maintenance. Reductions in color or polymer change-over times can significantly enhance operational margins by increasing equipment and labor uptime, allowing organizational assets to be more fully leveraged toward providing complete value to the manufacturing process.

Chem-Trend’s Ultra Purge™ brands of purge compounds cover a wide array of process applications, polymers, operating temperatures, and equipment types. They have been specifically developed to address the challenges faced by thermoplastics processors and add significant value to their operations.

Contact Us

Related

Chem-Trend supports your blow moulding process with efficient Ultra Purge™ purging solutions.

Ultra Purge™ purging compound optimises polypropylene (PP) colour change process from red to white.

Why Purge Compounds?

A Chem-Trend purging compound can purge all of your biggest frustrations and keep you moving forward. When compared to traditional cleaning methods, our purging products provide better cleaning, prevent unwanted stoppages, and save you money.

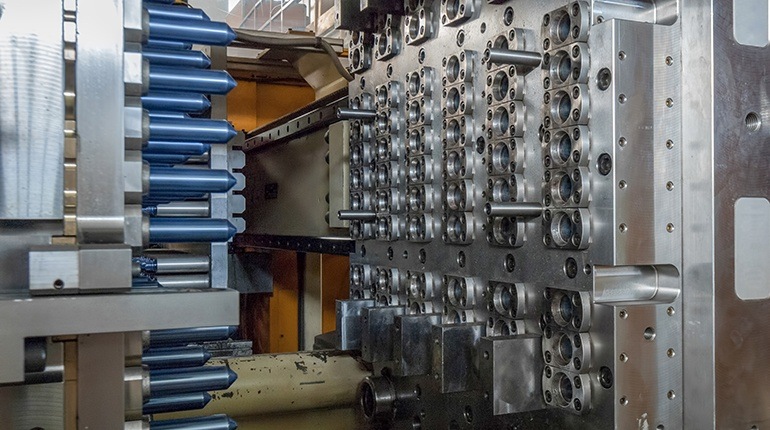

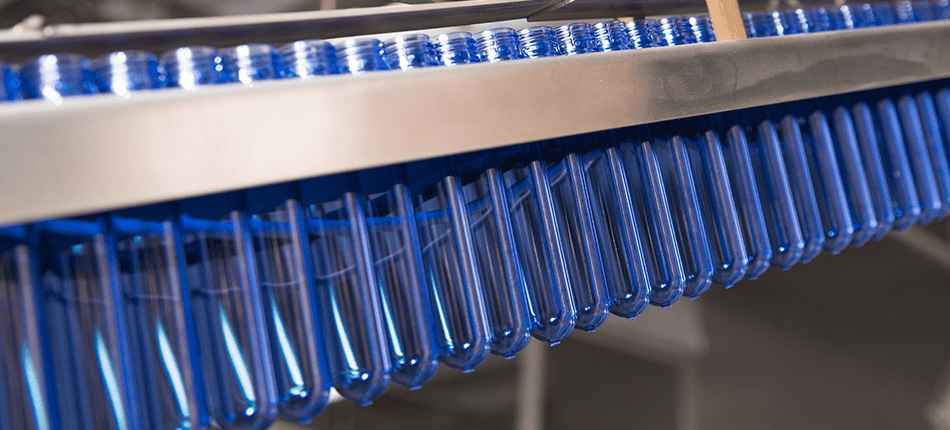

Preform coating system (PCS)

In-line solution installed right after the injection moulding machine with by-pass option

The Preform Coating System was developed in cooperation with BONINO GROUP and Steidle. It is an in-line solution that addresses core problems such as poor coverage and unwanted materials entering the preforms as well as scratches, jamming, loss of bottle definition and high shipping costs. Watch the video about this available plug-and-play technology solution.

The Problem of Black Spots

We all know the problem…the problem of black spots. When it comes to processing plastics, they lead to challenges, reduce productivity and increase the defects in your products.

A World of Colors

Chem-Trend’s Ultra Purge™ brand of high-performance purging compounds and Lusin® mould maintenance products deliver high-performance solutions for thermoplastics processors. It’s time…make the change for your operation!

Lost and Found

Did you lose something? Lost money due to increased downtime, increased scrap rates, reduced quality, reduced productivity? Let Ultra Purge™ highly efficient purging compounds, brought to you by Chem-Trend, help you find it again with greater operational efficiency and increased profitability.

Go with the Flow

Just as there is a perfect top for every pot, there is a right purge compound to fit the Melt Flow Index (MFI) of your caps and closure production. Chem-Trend’s Ultra Purge™ brand of purging compounds are formulated to address the challenges of MFI issues and can help you find the right purge to meet the different requirements of your production process.

Ultra Purge™: Purging via Part Production

Learn how to use production of parts as a means of purging your injection molding machine. Get the right technique for preparing and filling purging compounds for smooth operations.

Ultra Purge™: Purging the Injection Moulding Machine Screw and Barrel

Learn how to prepare and fill purging compounds for purging the screw and barrel in thermoplastics processing. Get the right technique for using purging compounds for smooth operations.

Viscosity / Melt Flow Index (MFI) of Purging Compounds

Learn about the viscosity/Melt Flow Index (MFI) of purging compounds used in thermoplastics operations.

Catalogue – Ultra Purge™ Purging Compounds for Automotive Applications

The Catalogue of Ultra Purge™ purging compound for automotive applications features purge solutions to manufacture high quality interiors & exteriors as well as lighting. Typical challenges such as avoiding streaks on PMMA or quick colour changes are solved by Ultra Purge™ purging compounds.

Catalogue – Ultra Purge™ Purging Compounds for Extrusion Applications

The Catalogue of Ultra Purge™ purging compounds for extrusion applications features solutions to address specific challenges in the manufacture of pipes & profiles, blow moulded containers, and sheet & film. On-the-fly, stops & restarts, no-residue grades are just some of the keywords worth being mentioned.

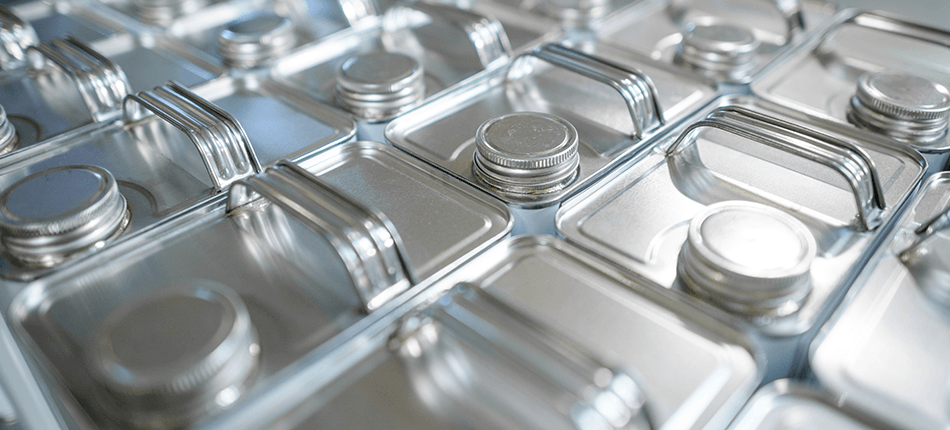

Catalogue – Ultra Purge™ Purging Compounds for Food & Healthcare Applications

High output rates, weight reducing trends in the packaging market, and food contact requirements are challenging topics. The Catalogue of Ultra Purge™ purging compound for food & healthcare packaging features purge solutions that solve typical challenges in the production of caps and closures, preforms, thin wall containers, cosmetic tubes, blow moulded containers and blown & cast films.

Catalogue – Ultra Purge™ Purging Compounds for Special Applications

Whether talking about specific screw removing solutions, removal of severe contamination when processing conductive polymers, or quick colour change in food approved transparent copolyester, Ultra Purge™ purging compounds are available to support thermoplastic processors.

Catalogue – Ultra Purge™ Purging Compounds for Technical Components Applications

Whether talking about specific screw removing solutions, removal of severe contamination when processing conductive polymers, or quick colour change in food approved transparent copolyester, Ultra Purge™ purging compounds are available to support thermoplastic processors.

Insights from a Technical Sales Expert on the Advantages of Ultra Purge™

A Technical Sales Expert explains how Ultra Purge™ purging compounds enabled a thermoplastics manufacturer to achieve seamless color changes. Following the implementation of the optimal solution, Chem-Trend provided on-site training to ensure the team achieved the best possible results.

FAQs: Purging compounds for injection moulding and extrusion in thermoplastics processing

What positive effects on production do specialized purging compounds provide? What are the different types of purging compounds available in the market? You can find the answers to these and even more questions in our FAQs.

Ultra Purge™ C6090

A solution that liquefies polycarbonates and doesn’t allow them to solidify during the temperature change process. This is primarily used for automotive headlamps and rear lamps. It’s one product that allows for a smooth transition between PC and PMMA.

Lusin® Mould Maintenance Products

Chem-Trend has developed a broad portfolio of Lusin® brand mould maintenance products for the thermoplastics industry. This portfolio is the result of nearly 70 years of Lusin® heritage, working directly with thermoplastics processors, understanding their challenges, and creating products that address their shop floor challenges.

Our mould maintenance line encompasses:

- Cleaners (including Degreasers)

- Lubricants

- Protective Agents (including Rust Preventatives)

Related

Lusin® Lub O 32 F: A product with a gamechanging impact.

At Chem-Trend, we believe in creating business-changing formulations that do more than merely release products. We believe they should release possibilities for better products, better processes, and better outcomes. With our new product, Lusin® Lub O 32 F, we are unleashing the potential of your thermoplastics operation.

Preform coating system (PCS)

In-line solution installed right after the injection moulding machine with by-pass option

The Preform Coating System was developed in cooperation with BONINO GROUP and Steidle. It is an in-line solution that addresses core problems such as poor coverage and unwanted materials entering the preforms as well as scratches, jamming, loss of bottle definition and high shipping costs. Watch the video about this available plug-and-play technology solution.

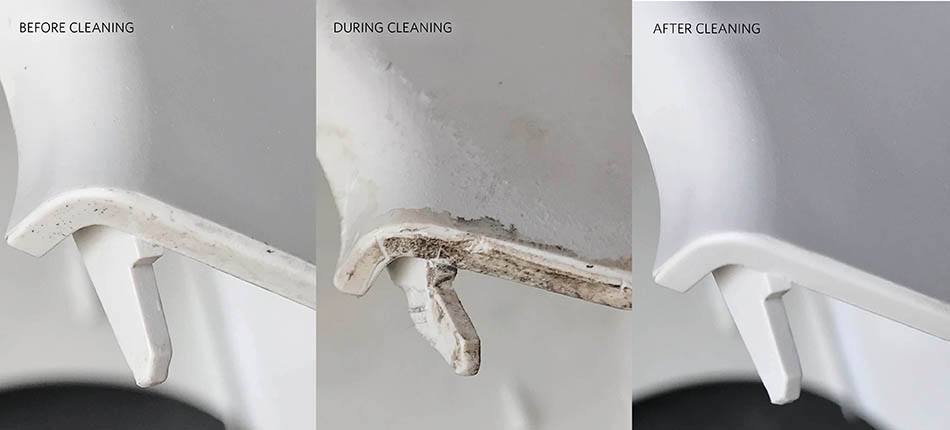

Lusin®: Clean and Degrease a Disassembled Mould

Learn how to properly clean, degrease lubricate and protect a disassembled mould. Get the right technique for applying Chem-Trend’s Lusin® mould maintenance products for smooth operations.

Lusin®: Clean, Lubricate, Release, Protect

Learn how to properly care for a built-in mold. Get the right technique for applying Chem-Trend’s Lusin® portfolio of products to clean, lubricate, release and protect for smooth operations.

Lusin®: Degrease a Built-In Mould

Learn how to properly care for a built-in mold. Get the right technique for applying Chem-Trend’s Lusin® degreaser to clean wax- or oil-based products from your injection moulding machine for smooth operations.

Lusin® Catalogue: Mould Maintenance Products and Release Agents

Our Lusin® mould maintenance and release agent solutions deliver the best possible support to increase efficiency and reduce costs in the production process. As a complete system, our Lusin® maintenance products complement each other ideally. Regular maintenance routines with our Lusin® mould cleaners & degreasers, mould protectants and lubricants ensure the best possible care and maintenance of your tools.

FAQs: Mould cleaners and degreasers for injection moulding and extrusion in thermoplastics processing

What is the difference between a mould cleaner and a degreaser (surface cleaner)? Do mould cleaners remove polyolefins? You can find the answers to these and even more questions in our FAQs.

FAQs: Lubricants for injection moulding and extrusion in thermoplastics processing

Is it possible to inhibit the transfer of lubricants for ejector pins to demoulded parts? How long does the lubricating effect last? You can find the answers to these and even more questions in our FAQs.

FAQs: Mould protectants for injection moulding and extrusion in thermoplastic processing

What kind of mold protectants exist and What are the advantages and disadvantages of

those different types of mold protectants? You can find the answers to these and even more questions in our FAQs.

FAQs: The Lusin® range of products for thermoplastics processing

What’s special about Lusin® products? Does Chem-Trend offer any Lusin® brand thermoplastics products approved for use in the food industry? You can find the answers to these and even more questions in our FAQs.

Lusin® Mould Release Agents

Optimization of cycle time, consistency of surface finish, and reduction of post-mold operations prior to painting or gluing are all important factors in thermoplastics processing operations. Chem-Trend understands these issues. With nearly 60 years of experience developing and manufacturing some of the highest-performing mold release agents around the world, for multiple industries and applications, we bring our experience, our foresight, and our hands-on approach to maximize your success. Our Lusin® Mold Release products are proven, respected, and best-in-class.

Related

Lusin® Catalogue: Mould Maintenance Products and Release Agents

Our Lusin® mould maintenance and release agent solutions deliver the best possible support to increase efficiency and reduce costs in the production process. As a complete system, our Lusin® maintenance products complement each other ideally. Regular maintenance routines with our Lusin® mould cleaners & degreasers, mould protectants and lubricants ensure the best possible care and maintenance of your tools.

FAQs: Release agents for thermoplastics processing

What are the advantages and disadvantages of silicone-free release agents compared to those containing silicone? You can find the answers to these and even more questions in our FAQs.

Video Overview

Here you can find an overview of all the videos that you can find on our page under the subject Thermoplastics. You can either stream these videos at the top of this page, or you can click on the links below to get to the video page.

Promotion Videos Thermoplastic

Ultra Purge™ Ultra-X™ – Purging As Easy As Child’s Play

Ultra Purge™ purging compounds

Ultra Purge™ 3615 purging compound is designed for fast residue free cleaning and easy screw pulls

Purging the Injection molding machine screw and barrel

Application videos Lusin® mold maintenance products

Clean and Degrease a Disassembled Mould

Clean, Lubricate, Release, Protect

instruction videos Thermoplastics

Viscosity/Melt Flow Index (MFI) of Purging Compounds

Preform Coating System (PCS)

In-line solution installed right after the injection moulding machine with by-pass option

Virtual tour R&D Laboratory and Technical Center, Maisach, Germany

Technical Articles

Please find some interesting Technical Articles below.

Return to top of the page

Related

Digital Catalogues

Just another click to reach our digital catalogues for thermoplastic processing: