- Purging Compounds

- Thermoplastics

- Prepare for a safe shutdown of your injection moulding machines and extruders for the summer break

- Attacking black specks during color and material changes in extrusion film processes.

- Catalogues for Thermoplastics Solutions

- Optimize your thermoplastics production with Ultra Purge™ purge compounds

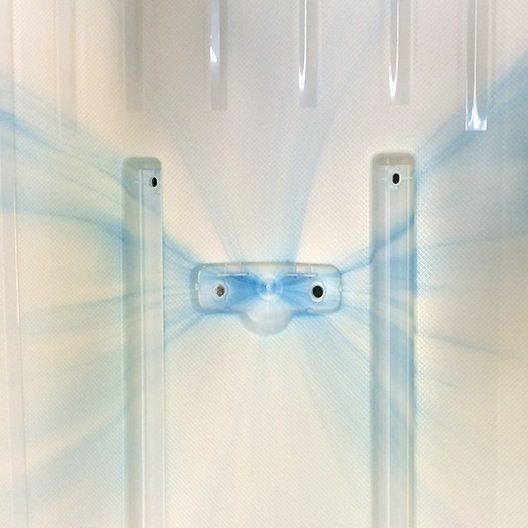

- Recyclable Purge Solution that Keeps the Bubble Up During Color Changes

Colour contamination at injection moulding and how to eliminate that

What it is:

Colour contamination, particularly when changing from dark to clear colour, occurs when previous colour is processed alongside the next processed polymer. It is especially critical to address this problem for change-overs to unpigmented (virgin transparent) polymers.

Causes:

In a thermoplastic processing environment, it can take a considerable amount of time to complete a colour change or return material to virgin transparent polymer status. The rapidity of a colour change can be influenced by pigment type, machine and process used, and polymer viscosity. Pigments impregnate the machine when processed for a long production run, and when injection moulding machines are fitted with a hot-runner or a stack mould, colour change could become extremely challenging due to the complexity of the tool itself. Any area where there is a lack of polymer flow can increase colour contamination issues.

Solutions:

The use of a purging compound that is compatible with your polymer and viscosity will help you save time and energy when performing the colour changing process.

Learn more about our whole Ultra Purge™ product range for different industry applications in our catalogues for thermoplastics solutions or contact us right away.

You’d like to see more of our CHEMPIONS? Follow us on LinkedIn and watch our videos in our feed. We are looking forward to welcoming you in our network.

RELATED CASE STUDIES

© 2025 Chem‑Trend L.P. or Chem‑Trend affiliated company. All rights reserved.

Regional websites:

-

Argentina

-

Brasil

(Brazil) -

Canada

-

Česko

(Czech Republic) -

CIS (excluding Russia)

-

Deutschland

(Germany) -

España

(Spain) -

France

-

India

-

Italia

(Italy) -

México

-

România

(Romania) -

Polska

(Poland) -

Türkiye

(Turkey) -

United Kingdom

-

United States

-

Việt Nam

(Vietnam) -

中国

(China) -

한국

(South Korea) -

日本

(Japan)

Notice

You are about to exit this page. You will be redirected to the Chem‑Trend Global website where you’ll find your requested content in English.

Continue