Rubber

- Release Agents and Mould Protectors for the Rubber Processing Industry

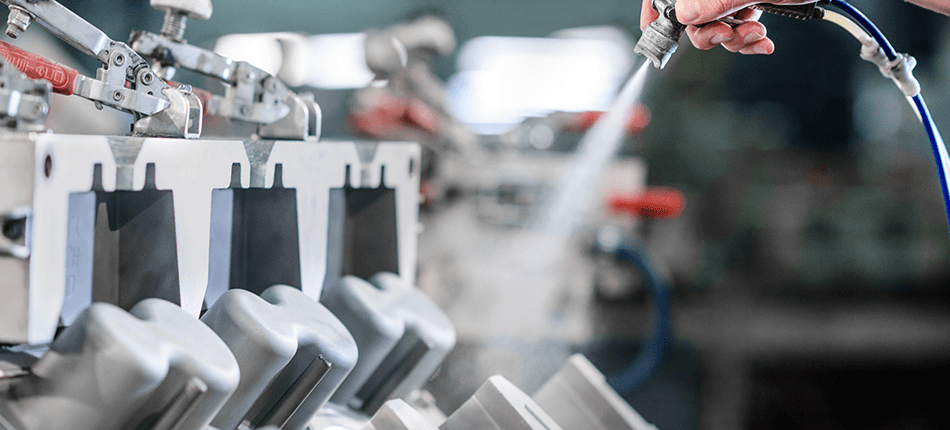

- Video on release agent application in fully automated rubber-to-metal moulding process.

- Semi-permanent Release Agents for Rubber Moulding

- Conventional Release Agents for Rubber Moulding

- Mould Cleaners and Protectors for Rubber Moulding

- Mandrel Lubricants

Release Agents and Mould Protectors for the Rubber Processing Industry

Chem-Trend is a global leader in providing release agents and related moulding process aids for use in a wide range of rubber moulding applications. With decades of proven experience in helping the world’s top rubber manufacturers, we have helped provide greater efficiency, higher-quality products, lower downtime, reduced scrap rates, and more predictability, as well as greater leaps in innovation. We serve rubber manufacturers in a number of ways:

Related

Driving force for manufacturing processes in e-mobility

The rise of electric vehicles (BEV, PHEV, HEV and eVTOL) is revolutionizing the automotive industry and presenting us with ever new challenges. For OEMs, this means increasingly stringent technical requirements and higher manufacturing costs, while maintaining efficiency, quality and cost effectiveness.

Video on release agent application in fully automated rubber-to-metal moulding process.

Chem-Trend supports the modern development of Industry 4.0 applications with our advanced release agent technologies and the advice of our experienced rubber specialists. As manufacturers move from manual to automated applications, they will find the expertise and reliability needed for a seamless transition at Chem-Trend. Our portfolio of semi-permanent release agents helps our customers increase productivity and efficiency, while also contributing to higher levels of sustainability.

Related

Chem-Trend’s semi-permanent release agent used in fully automated rubber-to-metal moulding process

Side by side with our customers towards Industry 4.0 – Rubber Injection Moulding

Semi-permanent Release Agents for Rubber Moulding

Semi-permanent release agents are state-of-the-art and provide the rubber moulding industry with an alternative to the traditional “shop-spray” or high-volume, apply-every-cure release agent. Chem-Trend has been developing these types of products for the rubber industry for nearly four decades now, and we provide them in either solvent- or water-based varieties. Our Mono-Coat® mould protectants and primers further enhance rubber and rotational moulding operations by extending mould life and improving the operational efficiency of moulds. Mono-Coat® anti-static agents and flange releases help improve part quality and molding efficiency in rotational moulding operations.

Watch our video:

Industry 4.0

Related

Conventional Release Agents for Rubber Moulding

In situations when semi-permanent release agents don’t work, we offer conventional mould release products. In fact, we continue to focus a significant amount of energy on the development of new products applicable to this specific section of the rubber industry. These conventional needs include situations with moulds featuring complicated cavities, and those that may require unacceptable over-application of the product to the areas that are easy to reach.

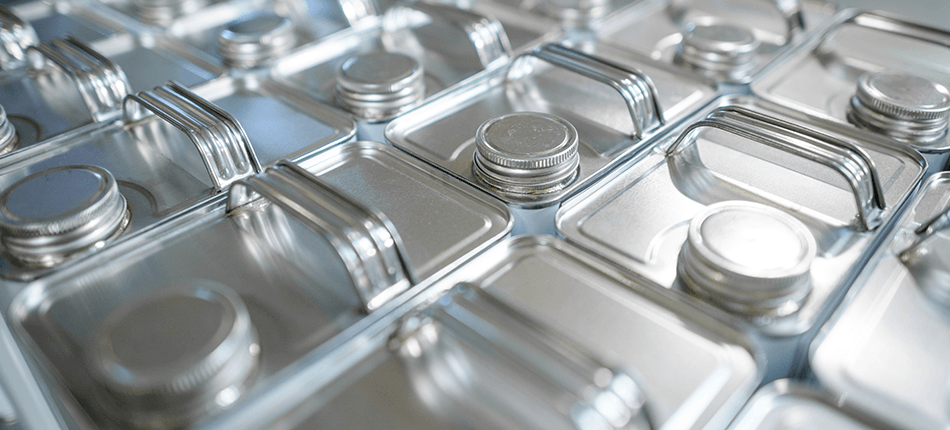

Mould Cleaners and Protectors for Rubber Moulding

Moulds often represent a significant investment in moulding operations. These tools are a key element in the operation, as they are directly related to efficiency, scrap rates, part quality, downtime, and operational costs. Keeping the moulds clean and productive is of critical concern to a profitable operation. Chem-Trend understands the importance of maintaining moulds in good working condition and has developed a line of high-quality mould cleaners and protectants.

Related

Chem-Trend’s In-Press Mould Cleaner (IPMC) easily cleans your mould in only 4 simple steps.

Chem-Trend IPMC is a mould cleaner, in the form of a rubber compound, used to clean moulds in process. Customers rely upon Chem-Trend to eliminate the need for offline cleaning while reducing down time, improving health and safety, and saving costs.

Mandrel Lubricants

Chem-Trend® mandrel lubricants are designed to provide lubrication for formed hoses made on rigid steel or aluminum mandrels, and to create a film that offers a slippery surface for straight but flexible hoses that are made on long-length nylon or rubber mandrels.

To learn more about how we have developed advanced products to address the specific challenges found in rubber manufacturing, contact us today.