Rotational Moulding

Rotomoulded parts come in all shapes and sizes, placing considerable demands on release agents to work perfectly under a variety of conditions. Based on Chem-Trend’s many years of experience at our customers’ facilities, we know how to optimise your moulding operation. Our release agents and processing aids for rotational moulding products come with access to a worldwide network of industry professionals committed to developing the right solutions and providing excellent individualised support.

Manufacturers of children’s playhouses, gasoline storage tanks and other products made using rotational moulding will experience undeniable efficiency and quality improvements using Mono-Coat® products. Specially formulated Mono-Coat® release agents and moulding process aids provide a distinct competitive advantage by delivering great looking, cost efficient products. Mono-Coat® is a secret weapon manufacturers can leverage for delivering flawless finish, while increasing productivity and consistency in their operations.

Related

Chem-Trend release agents and moulding process aids transforms rotational moulding

Mono-Coat® release agents and moulding aids such as Chem-Trend® Flow Promoter products provide value-adding solutions that improve rotational moulding manufacturing.

Mono-Coat® Release Agents for Rotational Moulding

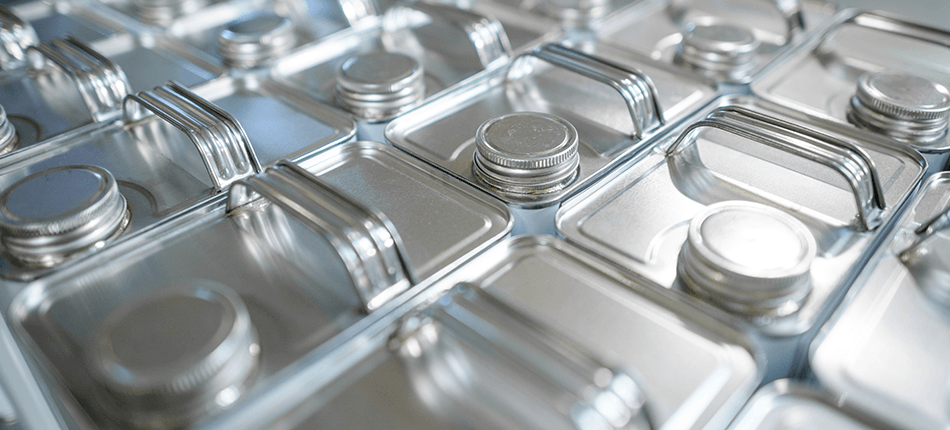

Our broad line of solvent- and water-based semi-permanent mould release agents for rotational moulding are specially designed and formulated to perform under all conditions. The Chem-Trend Mono-Coat® release agents are safe and easy to use, support rotomoulders in preventing surface abrasions and discolouration, and consistently deliver stable release even at high temperatures. Formulated to work with a wide range of polymers, including XLPE, HDPE, MDPE, LDPE and LLDPE, the reknown Mono-Coat® release agents for rotational moulding provide excellent release from multiple tooling surfaces (including stainless steel, steel and aluminium) with minimal transfer onto the moulded part.

Our mould release line for rotational moulding encompasses:

- Solvent-based release agents

- Water-based release agents

- Ready-to-use release agents

- Concentrate release agents

- Semi-permanent release agents

- Conventional one-time use release agents

benefits of Mono-Coat release agents include:

Minimised pre-release: Innovative Mono-Coat® products allow plastic material to stay in contact with the mould longer so parts retain their correct shape.

Easy release around flanges and vent-tubes: Purposely formulated Mono-Coat® release agents for the flange and vent-tube help plastic form perfectly, providing an extremely smooth finish.

Double-skin parts: Specially developed Mono-Coat® release agents ensure that the mould’s core can easily be removed.

Contact our industry experts for a consultation.

Free Consultation

Moulding Process Aids for Rotational Moulding

As a global leader in the development, production and supply of specialised mould release agents and mould process aids for rotational moulding, we help our customers to produce higher quality parts, more efficiently and at lower overall cost. Our portfolio is the result of many years of working directly with rotomoulders, understanding their challenges, and creating products that address their shop floor challenges.

Our Moulding Process Aids line encompasses:

- Anti-static coating

- Primers

Benefits include:

Optimised surface: Mono-Coat® anti-static coating applied before every moulding dissipates electrical charges and eliminates pigment swirls.

Improved gloss level: Mono-Coat® primer provides parts with a high-gloss finish, reducing or eliminating flame-polishing.

Contact our industry experts to learn how we can support you.

Request Free Consultation

Related

Chem-Trend® Flow Promoter for Rotational Moulding

The Chem-Trend® Flow Promoter is the perfect turn around for the challenges in rotational moulding that can make a very positive impact on the aesthetics of any rotationally moulded part.

In the early stages of the rotomoulding process, the tumbling resin sometimes has difficulty in reaching and remaining in the places where it is most needed. This can lead to a really poor appearance of your part, up to the point where pinholes (or sometimes even large holes) can form in the part surface. Flow Promoter provides you with the help that is needed in attracting the moulding resin to these potentially “starved” areas, thus ensuring that the moulded part takes on an even, blemish-free surface. Chem-Trend® Flow Promoter does not replace the release agent, but acts in complimentary fashion. Merely apply a liberal coating of Chem-Trend® Flow Promoter to the release-coated surface in the areas that experience tells you are susceptible to pinholing and then feast your eyes on blemish-free mouldings.

Benefits include:

- Reliable forming thanks to faster drying time

- Most effective surface improvement due to better coverage

- No visible fouling or build-up in the mould

- Consistent spray output due to anti-block nozzles

- Promotes complete powder coverage of mould surface in most difficult areas giving blemish free parts with minimal pinholing

- Excellent part replication due to better moulding of threads, insert encapsulation, complete edges and letter formation

Contact our industry experts to discuss how to get rid of pinholing.

No more pinholing

Related

Chem-Trend® Flow Promoter: A smart way to enhance rotational moulding

Even the most well-designed moulds and rotational moulding operations can benefit from Chem-Trend® Flow Promoter, a speciality product that helps improve productivity, cost, quality and customer satisfaction.

Flow Promoter promotes complete powder coverage of mould surface in rotational moulding

Flow Promoter promotes complete powder coverage of mould surface in most difficult areas giving blemish free parts with minimal pinholing.