Friction

Conquer the challenges of moulding friction components with high-performance release agents.

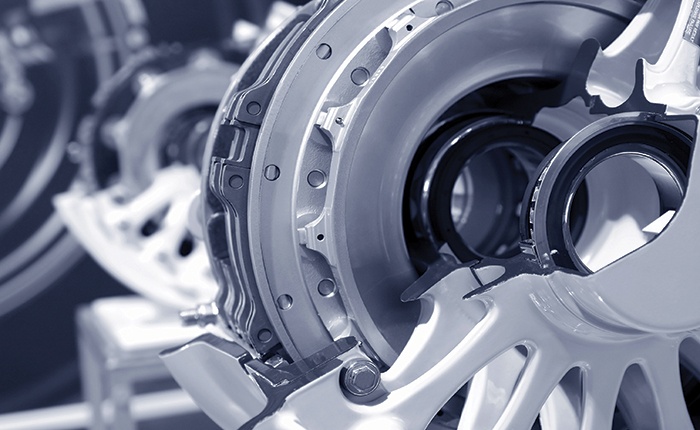

When producing friction components there are numerous unique challenges. The manufacture of components such as brake linings, brake pads, and clutch assemblies – for brake systems and powertrains within the transport and machinery sectors – is a challenging process with a range of potentially problematic issues. A highly-effective advanced mould release agent will help you to meet your operational challenges and specific requirements, while at the same time:

The combination of abrasive compounds and curing binder resins used to produce highly wear-resistant surfaces require an advanced mould release agent allowing contamination-free release, protecting your moulds, minimizing cycle time and maximizing uptime. Working together with manufacturers over a number of decades has enabled us to develop high-performance release agents which combat typical issues, and are compatible with post-moulding processes. Many years of field and laboratory experience also mean we are able to deal with unusual issues and develop highly specialized products for your specific needs.

The Chem-Trend mould release agents for friction components enable:

- High dilutions

- Low deposits on mould surfaces

- Exceptional release properties

- Significantly reduced scrap rates

- Enhanced productivity

For related case studies, read on — or reach out to us today for a free consultation.