Die Cast

- Die Lubricants, Plunger Lubricants and Ancillary Products for Die Casters

- Die lubricants (release agents for the die casting industry)

- Plunger lubricants

- Ancillary products

Euroguss 2026

Die Lubricants, Plunger Lubricants and Ancillary Products for Die Casters

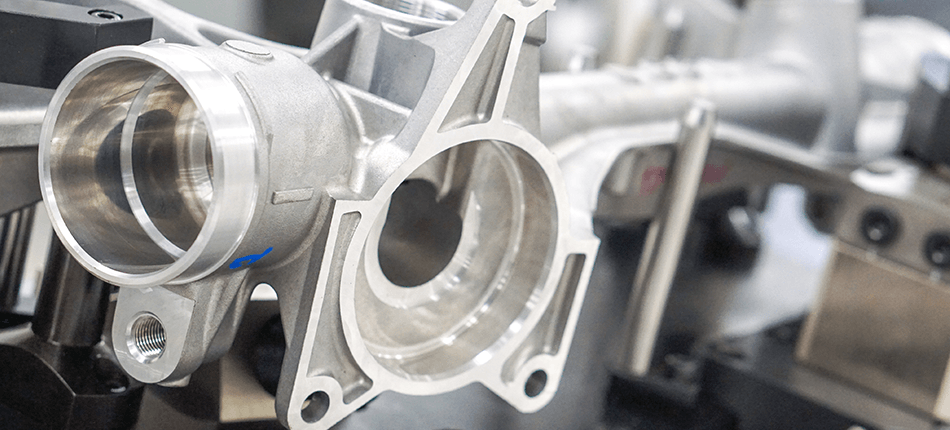

Working with our customers, we help unleash potential. Due to the uniqueness of each of these processes, as well as the diversity of the raw materials utilized, we fulfill exacting needs with solutions that maximize efficiency. Die cast release agents and chemical specialities must be designed to perform brilliantly in the harshest of conditions and materials. Our unique, robust, formulated products have been developed to serve as plunger lubricants and die lubricants that meet or exceed expectations. All with an eye toward delivering better results and processes.

Our highly regarded dilution products are best-of-breed, and designed to create exceptional ease and value. Our innovative portfolio is based on an extensive suite of polymer technologies developed and synthesized to specifically provide exceptional on-die performance, helping die casters see less downtime and higher-quality rates due to lower levels of porosity.

In addition to products, we also proudly offer to help optimize effectiveness. Like our High Efficiency Release Agent (HERA™) micro-spray technology that revolutionizes release agents, allowing customers to applying far less agent. This allows for maximum efficiency using minimal product, and creating a new paradigm in manufacturing potential.

Related

Discover the future of sustainable die casting with HERA™

Dive into the world of HERA™, a pioneering die lubricant that’s enhancing sustainable die casting and leading us towards a more sustainable tomorrow. Discover the power of micro-spray technology and join our seasoned experts at Chem-Trend as they share insights on how HERA™ is transforming the industry and contributing to a more sustainable future.

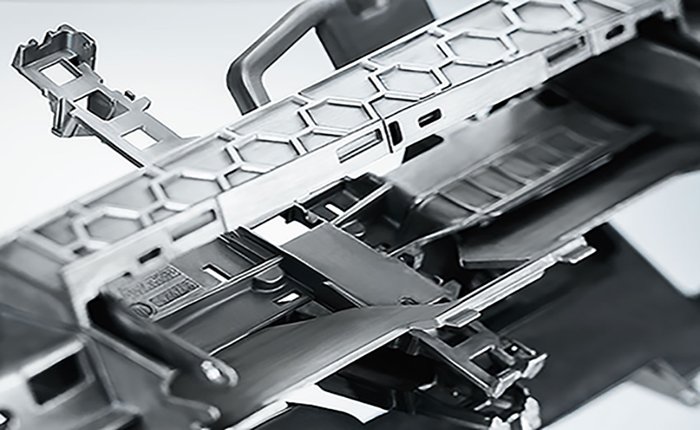

Driving force for manufacturing processes in e-mobility

The rise of electric vehicles (BEV, PHEV, HEV and eVTOL) is revolutionizing the automotive industry and presenting us with ever new challenges. For OEMs, this means increasingly stringent technical requirements and higher manufacturing costs, while maintaining efficiency, quality and cost effectiveness.

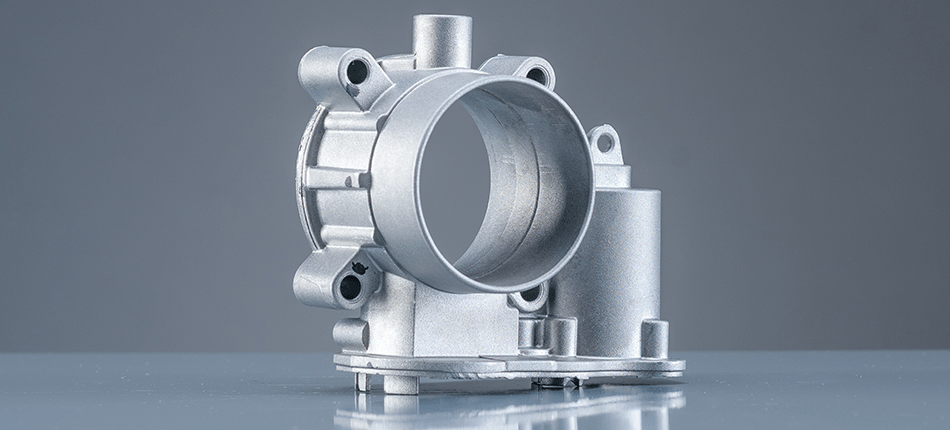

Die lubricants (release agents for the die casting industry)

Our die lubricants are engineered to actually enhance your processes, allowing you to gain efficiency. Die lubricants can be engineered to provide exceptional release and die/solder protection with optimized wetting, promote metal flow, quickly cool die surfaces, and maintain a die temperature within a narrow band, all of which allow for faster cycle times and longer die life.

Related

HERA™ High Efficiency Release Agent for micro-spray application in die casting

Why change from a traditional die lube to a high efficiency release agent?

HERA™ die lubricants for micro-spray applications in die casting

HERA™ was specifically developed as a ready-to-use advanced technology water-based die lubricant. Learn more about its advantages in today’s complex applications.

Chem-Trend’s HERA™ — High Efficiency Release Agent — die lubricant helps manufacturers reduce scrap, downtime and energy use. Its water-based formulation can be used in a variety of applications, and its performance characteristics make it an ideal solution for both high and low temperature operations.

HERA™ Light die lubricants for die casting incl. UV-formulation

HERA™ Light die lubricants are further developments of HERA™ products and offer a completely new alternative to conventional dilution spraying, while still providing the advantages of the established HERA™ quality. HERA™ Light helps die casters to increase productivity in many respects while achieving a sustainable reduction the required energy and resources.

Chem-Trend® SL-6XXXX Release Agent Series

Chem-Trend developed the first effective water-based release agent (die lubricant) over fifty years ago. Since then, Chem-Trend’s continual innovation steadily evolved our product line setting new standards in the die casting industry. The Chem-Trend® SL-6XXXX release agent series offers a comprehensive product range for the requirements of the processing industry and facilitates a demonstrable improvement in diverse associated procedures.

FAQ

Gas porosity can occur when the turbulence of the molten metal traps gas inside the casting. Excess die lubricant can create more gases in the cavity that may contribute to gas porosity. High efficiency die lubricants do not contribute significantly to gas porosity.

The main source of smoke is usually the plunger lubricant. These are usually organic compounds and there is a tendency to overfeed these products. High efficiency and low smoke plunger lubricants can minimize the smoke in a foundry. Die lubricants are usually water-based products and therefore are not major contributors of smoke. Some oil-based die lubricants can produce smoke but are typically fed at very low dosages and so the quantum of smoke produced is not significant.

The paintability of a casting is more dependent on the efficiency of the cleaning process. Silicone containing die lubricants can be used to make paintable parts, but they must be easily cleanable by most cleaning processes. Because of the wide variation in the types of cleaning process and the cleaners used, we advise customers to check the efficiency of cleaning before finalizing the product.

COD stands for Chemical Oxygen Demand and all organic compounds create COD. In the case of die lubricants, typically a significant amount of the organic materials can be removed by precipitation or filtration as described above.

Die lubricants that are designed to rapidly cool and adhere to the die surface form a protective film that prevents solder and provides lubricious release of the casting. This can reduce both the cycle time and down time, improving productivity.

The dilution ratio of die lubricants can be checked by using a LaMotte meter. A sample of the dilute die lubricants is placed in the instrument and the reading is compared against a standard calibration curve. Automated systems for checking the dilution automatically are also available.

Read more about our DilutionIQ.

Water based die lubricants are typically emulsions of oils and other actives in water. The size of the emulsified particles is an important issue. Small particles can be removed in conventional precipitation style waste water systems using alum and lime or similar reagents. They can also be removed by semi-permeable membranes like UF and NF although these may have a tendency to foul (depending on the type of membranes used). The removal efficiency depends on the type of process used.

While die cooling is an intrinsic property of many die lubricants, it is not the most important property. For some applications a lot of cooling may be undesirable as it can adversely affect the filling of the cavity with molten metal. Other applications may involve dies with little or poor internal cooling. For these applications a die lubricants that can cool very efficiently would be desirable.

There is no one optimal ratio; this has to be established for every machine and application. The ideal dilution ratio is one that provides the right amount of lubricant film in the shortest spray time possible.

We suggest using soft water for diluting water-based die lubricants. Water with up to 100 ppm of total hardness has been used with no adverse effects. Very pure water (less than 10 ppm hardness) can lead to corrosion problems on the die, while high hardness water can lead to other problems like spray nozzle plugging and in cavity build-up. Using good quality water can reduce downtime and give better quality castings.

Typically plants use either a centralized system (which serve a number of machines), or individual dilution tanks which are dedicated to one die cast machine. Centralized systems simplify the task of making dilutions and can save cost of equipment. The disadvantage is that if different die cast machines have different operating conditions, it will be difficult to change the dilution ratio or the die lube. Individual dilution tanks allow very tight control of dilution and are preferred when part quality is of very high importance.

Read more about our DilutionIQ.

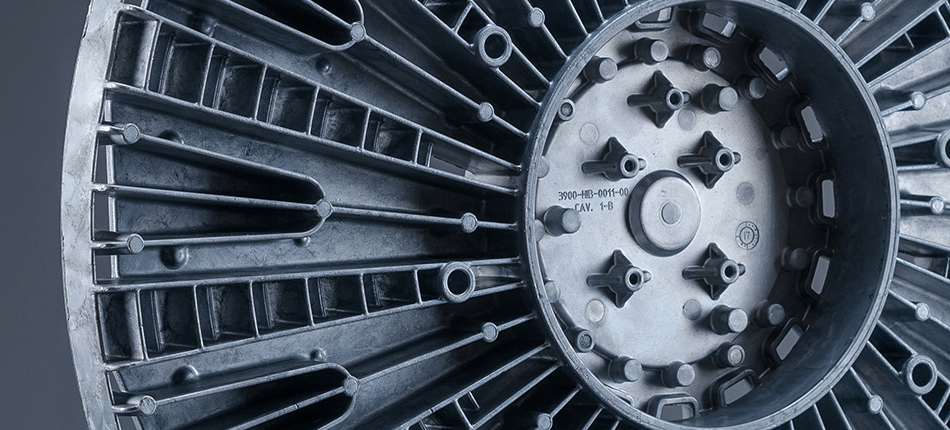

Plunger lubricants

Plunger lubricants are used to minimize the wear to the plunger tip and sleeve, thus increasing its lifetime and reducing the downtime for replacement. They also help provide a seal around the tip to prevent intensification pressure issues from molten metal leaking around the plunger tip which also causes mechanical problems and additional wear. Chem-Trend makes a wide range of products to protect the shot-end components and assist in the production of high-quality castings, while minimizing any adverse environmental effects.

Related

Discover Chem-Trend® PL-760: The Future of Die Casting Lubrication

Discover the future of die casting lubrication with Chem-Trend® PL-760. Our eco-friendly plunger lubricant delivers high performance, ensuring reliable operation under demanding conditions while safeguarding your team and the environment.

Unlock unparalleled performance and eco-friendly benefits with Chem-Trend® PL-760. Our advanced plunger lubricant ensures high load capacity, strong adhesion, and excellent temperature stability, all while being environmentally responsible.

Plus, explore our precise MicroDose™ application unit, designed for optimal lubrication efficiency and reduced lubricant consumption.

Download the flyer to learn more about how PL-760 and MicroDose™ can revolutionize your die casting operations.

Discover Chem-Trend® PL-773: Unyielding Black Armour

Experience superior wear protection and high performance with Chem-Trend® PL-773. Our innovative plunger lubricant, engineered with advanced graphite technology, ensures reliable die casting operations under extreme conditions.

Unlock the next level of die casting lubrication with Chem-Trend® PL-773. Engineered with special active ingredients and colloidal graphite, PL-773 offers improved wear protection and emergency running properties, ensuring smooth and efficient operations.

Plus, explore our precise MicroDose™ application unit, designed for optimal lubrication efficiency and reduced lubricant consumption.

Download the flyer to learn more about how PL-773 and MicroDose™ can enhance your die casting processes.

Ancillary products

Die casting is a complex process with intricate machines and a number of processing steps. Since all of these can have an impact on the quality of the product and the overall productivity of the plant, Chem-Trend has developed a complete range of offerings to serve the specialized needs of some of these stages. These include:

- Hydraulic Fluids

- Anti-Soldering Waxes

- Hot Spot Greases

- Ladle Coatings

- Ejector Pin Lubricants

- Quench Compounds

- Trim Press Lubricants

- Cleaners (for example Chem-Trend® DC-456)

- Corrosion Preventers

- Assembly Lubricants

- Toggle Lubricants

We are constantly developing new and breakthrough products and cutting-edge solutions to help our customers release a new level of manufacturing potential.

Related

Wolfrakote TOP and Chem-Trend® TOP-211 ladle coatings for die casting

For high temperature applications in die casting, temperature loss of molten metal and soldering in ladles and runners are two major challenges.

Chem-Trend offers long-term coatings for die casting processes of non-ferrous metals (HPDC, LPDC, hot chamber, cold chamber, gravity casting etc.). These coatings are especially suitable for protecting cast iron and steel tools when in contact with molten aluminum – e.g. pouring ladles and runners.

Wolfrakote TOP and Chem-Trend® TOP-211 ladle coatings serve as dry lubricants with excellent adhesive properties even for processes with aggressive alloys.

Chem-Trend® HS-141 B and Chem-Trend® HS-161 for smooth production start-up phase of your dies

In the dynamic world of pressure die casting of non-ferrous metals, efficient start-up processes are crucial. To avoid high tensions in the mould and tool surfaces, aligning the temperature difference between casting and mould is essential. Pre-heating and the right lubrication also improve casting quality by enhancing metal flow. Thus, the risk of cold flow incomplete die filling, gas inclusion, or porosity in the castings are reduced significantly. Chem-Trend® HS-141B and Chem-Trend® HS-161 play a pivotal role during the start-up phase of the die. Their performance allows for a faster production start.

Anti-soldering waxes for die casting

For the challenge of metal soldering on the tools and mould surfaces in die casting, our specially formulated anti-soldering-waxes Chem-Trend® ASW-102 and Chem-Trend® ASW-104 provide an efficient solution. Our anti-soldering-wax can be applied preventively during production, preparation or maintenance. If soldering occurs during production, our products form an adherent bond with the solder, which could help to remove it from the tool steel during subsequent shots.

Advanced ejector pin lubricants for die casting

Independent of which process you use in die casting, be it HPDC, LPDC or GDC, in the critical phase of releasing the cast part from the mould, the reliable performance of ejector pins is essential. Our lubricants are specifically formulated to reduce friction, prevent wear, and ensure consistent operation of ejector pins. Without proper lubrication, ejector pins can experience increased friction and wear, leading to frequent breakdowns and costly downtime.

Quench Compounds for Die Casting

Our water-based, non-flammable quench compounds cool down your cast parts efficiently and reliably. Our products spread evenly on your parts surface and create a protective lubricating film against corrosion. At the same time, they mildly clean off casting residues. In this way, your parts are best prepared for further steps like trimming, machining, sand blasting etc. However, the quenching compounds themselves can easily be washed off with water respectively by the help of a mild alkaline cleaner so that further treatments are not affected either.

Trim press lubricants for die casting

In the high-pressure world of die casting, every detail counts, and this applies also to the trimming process. Trim press lubricants are essential for ensuring clean, precise cuts and protecting valuable tooling from excessive wear. Our specialized lubricants are used during the trimming phase of die casting, where excess material (flash, runners, gates) is removed from cast parts using mechanical or hydraulic trim presses.

Chem-Trend’s biodegradable HFE hydraulic fluids offer the power of 4×4

Experience the ultimate in hydraulic fluid innovation with Chem-Trend® HFE. Enhance equipment performance and lifespan, ensure a safer workplace, support sustainable practices, and trust in top-tier reliability and support. Discover the 4×4 benefits today! Download the brochure.

To learn more about how we have developed advanced products to address the specific challenges found in die casting operations, contact us today.