Release Agents

Global leaders in release innovation.

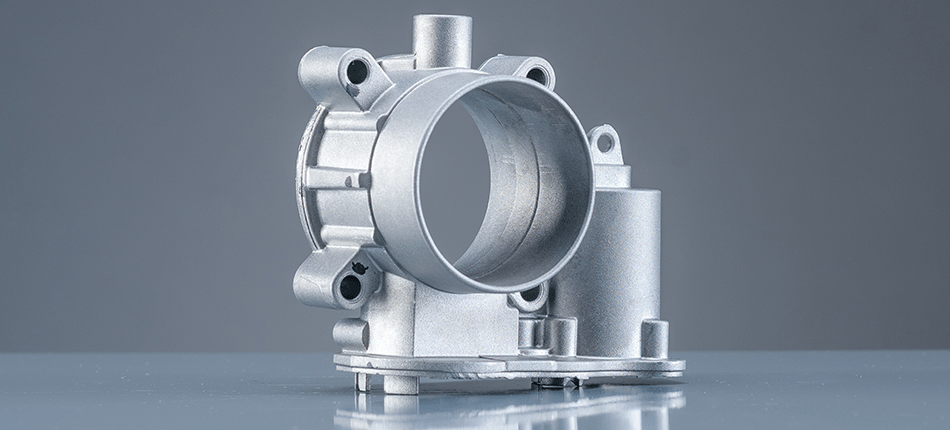

Release agents are an integral part of many manufacturing processes. Specialty release agents can help you enhance productivity, extend tool/die/mold life, increase cycle times, improve part/surface quality, and reduce scrap and defect rates, along with many other potential benefits.

We work closely with you and your team to find the precise release agents to improve your processes.

Conventional Release Agents

We offer a broad portfolio of conventional (apply-every-cycle) mold release agents to meet the needs of our customers. Our conventional (sacrificial) mold release agents are:

- Available water-based or solvent-based

- Formulated as ready-to-use or dilutable, depending on the application

- Suitable for multiple types of spray equipment

- Capable of “tailored” dilution rates, depending upon the application and amount of slip required

- Excellent for molded parts with very complex geometry

- Exceptionally low in in-mold buildup/mold fouling

Semi-Permanent Release Agents

You can leverage a number of potential advantages with today’s highly sophisticated water-based or solvent-based semi-permanent mold release agent technologies. Semi-permanent mold release technology has provided industries with a viable alternative to the traditional “shop-spray” or high-volume, apply-every-cycle release agent. Our customers have experienced:

- More mold releases between applications than conventional release solutions

- More molding cycles attained per working shift

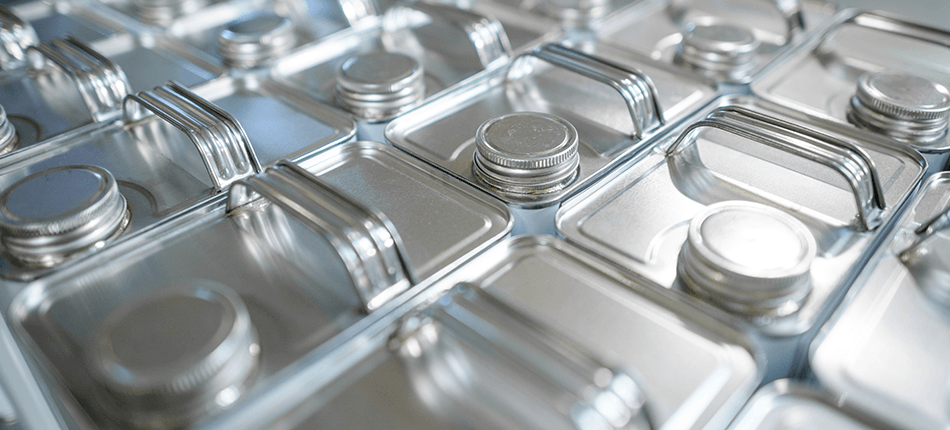

- Small amount of product needed per application, contributing to a cleaner working environment with fewer storage needs

- Reduction in overall scrap

- Molds can remain in production for extended periods of time due to the protection properties provided

- Supports production of complex part/mold structures due to ease in application exactness

- Molded parts retain consistently good cosmetic appearance

Silicone-Free Release Agents

Always on the cusp on innovation and sustainability, Chem-Trend has developed a robust range of release agents that do not utilize silicone. Silicone-free release agents provide a number of benefits:

- Reduce oily residue, allowing for easier painting and coating post-release

- Reduce contamination risk and remove costly steps from the manufacturing processes

- Provide for the removal of costly and time-consuming steps in the manufacturing process of many components, thus increasing productivity and lowering your operational cost

Why should you choose Chem-Trend release agents?

True value

Creating value for you, our customer, is our focus. Formulated to optimize your daily operations, our industry-leading line of release agents includes water-based and solvent-based products as well as silicone and silicone-free products in semi-permanent or apply-every-cycle products. Our solutions can help you overcome costly manufacturing challenges — and leveraging the power that release agents offer to improve operational efficiencies and product quality.

Maximized productivity

Chem-Trend offers a wide variety of release agent options suited to address your specific needs and maximize your results. Every molding process is unique in some way, and optimal release requires unique solutions. Our team of localized experts takes a hands-on approach, working with you to identify all areas of potential improvement. Our research and development team then designs individualized solutions for your operation.

Proven sustainability

Many of our customers are working diligently to make their operations more sustainable. They choose Chem-Trend because we’ve been focused on minimizing the environmental impact of our products since we began. We developed the first commercially viable water-based die lubricant in the 1960s, which had an immensely positive impact on the health and safety aspects of die cast facilities by removing the use of graphite and/or solvents in the die lubricants that were widely used at that time. Continual efforts extend to a variety of other environmental impact concerns, including the use of VOCs in solvent-based mold release agents. Today Chem-Trend leads the industry in the development of innovative solutions.

NEWS

RELATED THINKING

Aluminium Die Casting: Lubrication Technology and Trends

Innovative Die Lubricant Trends for Evolving Productivity and Process Requirements

Innovative Technologies in Die Lubricants

Magnesium Die Casting Lubrication Technology & Trends

Releasants: Attachment of Coatings and use of Anti-Static Supplemental Products

The Effect of Die Lubricant Spray on the Thermal Balance of Dies

Water Conservation through the Utilization of Advanced Performance Die Lubricants

Greater efficiency and sustainability with the right release agent

BROCHURES

Chem-Trend and Imerys Metalcasting Solutions

Chem-Trend and Imerys Metalcasting Solutions pool their development expertise for sand foundries.

A co-operation with added value

The partnership between Chem-Trend and Imerys Metalcasting Solutions offers the global market an innovative premium product portfolio of chemical specialities for sand

casting. This cooperation provides customers with a comprehensive, well-engineered product range for the production of high-quality sand moulds and cores from a single

source.

Chem-Trend release agents and moulding process aids transforms rotational moulding

Mono-Coat® release agents and moulding aids such as Chem-Trend® Flow Promoter products provide value-adding solutions that improve rotational moulding manufacturing.

Chem-Trend® SL-6XXXX Release Agent Series

Chem-Trend developed the first effective water-based release agent (die lubricant) over fifty years ago. Since then, Chem-Trend’s continual innovation steadily evolved our product line setting new standards in the die casting industry. The Chem-Trend® SL-6XXXX release agent series offers a comprehensive product range for the requirements of the processing industry and facilitates a demonstrable improvement in diverse associated procedures.

Lusin® Catalogue: Mould Maintenance Products and Release Agents

Our Lusin® mould maintenance and release agent solutions deliver the best possible support to increase efficiency and reduce costs in the production process. As a complete system, our Lusin® maintenance products complement each other ideally. Regular maintenance routines with our Lusin® mould cleaners & degreasers, mould protectants and lubricants ensure the best possible care and maintenance of your tools.

FAQ

The industry and process demands heavily influence the transition. Due to safety, environmental, and other regulatory concerns, several sectors no longer accept items made with solvents. Most water-based release agents are used in industries including die casting, tyre production, and general rubber moulding. While the thermoplastics and composites sectors currently utilise a majority of solvent-based release agents, the polyurethane business uses both water-based and solvent-based mould release agents.

In comparison to solvent-based formulations, water-based products are more sensitive to application, posing more difficulties for the development of films, and have slower evaporation rates (which can be controlled by the application method, process conditions, and environment humidity levels). Water-based products are more likely to result in a chemical reaction between any remaining water on the mould surface and the material being moulded during the moulding process (for instance, polyurethane moulding can produce urea by-products). To ensure emulsion stability and bioactivity resistance, this type of release agents also needs more advanced technology. To use water-based release agents in a larger range of sectors, these difficulties must be overcome.

The ideal way to apply non-aerosol goods is using a high-quality spray gun or with clock-controlled spraying equipment.

The chosen carrier, the release agent’s characteristics, the process and its surroundings, as well as the process itself, all influence application approach. Application is an important factor to pay attention to because it can have a big impact on how well the release agent works. Release agents are typically sprayed with a spray pistol (either manually or automatically). Multiple spray nozzles programmable spray systems with the ability to apply one or more release agents are employed in various applications. The nozzle size is controlled to guarantee proper atomisation and good film formation (affected by the anticipated throughput and release agent viscosity). Spray application can be airless (where the release agent stream is sheared at high pressure by the nozzle to achieve the required atomisation) or air-assisted (where air is utilised to further shear and atomise droplets). Solid and liquid release agents can also be applied using electrostatic spray guns. For some uses, release agents can also be sprayed with aerosols or even by manually or automatically coating surfaces.

Each type of agent has distinct strengths (S) and limitations (L). Here is a quick breakdown by release agent type:

Solvent-based release agents:

S: Simpler to use. The solvent carrier aids in the development of the film. Depending on the mixture of the solvents, the evaporation rate can be changed. The active components in the release agent may dissolve or disperse more easily depending on the solvent used.

L: Not particularly eco-friendly. Bring more safety and health risks (fire dangers) compared with non-solvent based solutions.

Water-based release agents:

S: Non-flammable and beneficial to the environment. Can sometimes be shipped in concentrates and may be possible to dilute. If necessary, they can be employed to chill the die. Might also be created with technology that guarantees mould release agents operate on par with solvent-based release agents.

L: Require more sophisticated manufacturing technology. The correct formation of films can be more difficult. This group of release agents might be more vulnerable to deterioration and biological attack. Water-based release agents may not be suitable for all room temperature moulding processes or operations with short cycle periods since they evaporate more slowly than their solvent-based counterparts. Entrapped steam or even chemical reactions with the material being moulded could be caused by residual water on the mould. The latter is especially problematic when moulding polyurethane components.

Carrier-free Release Agents:

S: Due to the lack of a carrier, it can be used “as is”. No vapours are released. Application noise is reduced. Doesn’t need tank storage or dilution. Zero waste stream.

L: If improperly applied, can pose a dust danger. Necessitate the use of specialised application equipment, frequently electrostatic spray guns, which could be expensive to purchase. To guarantee that the mould is thermally balanced while using carrier-free release agents, extra adjustments to the moulding apparatus may be necessary. These factors frequently restrict the use of this group of release agents.

Sacrificial Release Agents:

S: Simple to use. Lessen the requirement for application technique and increase work tolerance (reducing reliance on qualified workers).

L: If applied excessively, tends to build up on the mould. The release coating generally transfers in part to the moulded part, which could have adverse effects on subsequent post-moulding processes (painting, adhesion, etc.) if applied excessively or if the chemistry of the release agent is incompatible with the process. If water-based, they have a tendency to cool the mould, taking heat and energy out of the system (this could be a drawback if the process is bot set up accordingly).

Semi-Permanent Release Agents:

S: Because the release agent film lasts for several moulding cycles, they require substantially less frequent application than sacrificial release agents (the frequency is dependent on the process parameters). Enables release agent application to be done in a more continuous, constant manner. It is possible to do ehanced post-moulding operations (coating, adhesion) since there is very little transfer to the moulded object. On the coated mould, the release agent can be reapplied frequently to renew the release agent film. In order to prevent build-up and give the desired release performance, this category of release agents offers a very good combination of chemical and physical barriers.

L: Operators must receive further training to guarantee that the proper touch-up frequency is followed. For the initial application of the release agent to work well and effectively with the mould surface, the moulds must be clean.

Internal Mould Release Agents:

S: Reduce the use of outside mould release agents.

L: Over time, it may continue to move out to the surface, endangering the part’s surface aesthetics or post-moulding operations (coating and adhesion). As internal mould release agents may not always migrate to the mould interface or may not guarantee a 100% release efficiency, they frequently do not completely eliminate the necessity for external mould release agents. They are constrained in their capacity to carry out high performance release agent functions, such as changing the part surface properties.

The benefit of release agents containing silicone is that they provide an excellent release effect. The drawback of silicone-containing release agents is that it may be difficult or perhaps impossible to handle the released pieces in the future, such as when adhesive bonding or painting. There will be a need for further post-moulding part processing.

Mould release agents impact process characteristics like the flow rate of the material being moulded within the mould cavity, moulding cycle time, and, of course, release ease in addition to providing a physical and/or chemical barrier as a means of separation between the material being moulded and the mould surface. In addition to impacting the mould service life between maintenance cycles and overall productivity, the choice of mould release agents also has an impact on the finish characteristics of the released part, such as gloss level, accurate texture reproduction, post moulding operations (such as adhesion or coating of the moulded part), and gloss level.

The following factors should be taken into account while choosing the right release agent:

- Substrate or mould material

- Substance being moulded

- Process conditions

– Temperature

– Pressure

– Line speed / cycle time

– Particular moulding processes, such as compression, high pressure, gravity fill, and injection moulding.

– Variances in the process - The shape of the mould

- Post-moulding operations (coating, adhesion)

- The performance and productivity levels anticipated (the quantity of good releases or good parts removed from the mould in each time period).

- Current process problems (difficulties with cavity filling, soldering, release-related scrap rates, changes in process condition, etc.).

- Expectations for maintaining moulds (frequency of mould cleaning)

- Conditions for part finish (gloss level, surface defects, etc.)

- Health, Safety, and Environmental (HSE) requirements

- Application methods

Applying too much release agent might result in an oily or slippery surface on the moulded component, making further process treatment of the parts more challenging.

The spray valve mechanism in aerosol cans makes it possible to apply the substance very thinly, uniformly, and with a predictable spray pattern, which is advantageous. This makes it possible to preserve the material and avoid applying it too much. Spray cans are versatile and easy to handle.

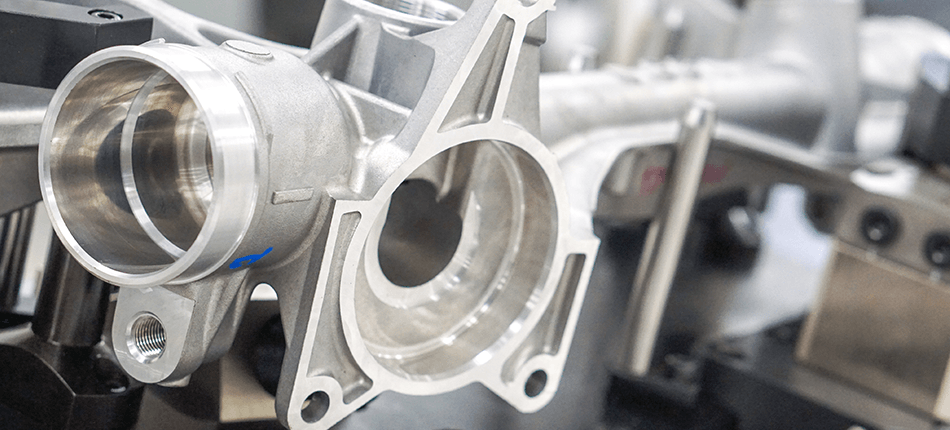

Heat transfer, part dimensional properties, aesthetic appeal, and process effectiveness are all adversely impacted by build-up of release agents, the material being moulded, or by-products and residues created by chemical reactions that happen inside the mould cavity (in situations where the compound is chemically changed during the moulding process). To ensure the quality of the parts, mould cavity fouling must be routinely cleaned manually or chemically. Productivity is lost each time the mould needs to be cleaned in-situ or maintained in another way.

Two main factors might cause build-up problems:

The mould has an excessive amount of release agent.

This might be the outcome of choosing the wrong release agent for the job (one that isn’t compatible with the process temperature, for example) or applying too much release agent to the mould.

A build-up of the material being moulded or of by-products and residues produced during the moulding process results from a lack of a release barrier.

The selection of release agent in this instance might not be suited for the process circumstances (inadequate for the process temperature, poor film formation, etc.). The lack of physical and/or chemical resistance of the release agent to the substance that then penetrates the release agent film and physically or chemically attaches to the mould may also be the cause of this (i.e., there is not enough release agent film present on the mould).

To make parts that perform better under the increasingly demanding operating circumstances of the finished goods, industries are moulding more unusual materials. These rare materials are sometimes difficult to mould. The automotive industry is one excellent example, where engine components (moulded parts) must overcome chemical and physical obstacles in order to sustain more demanding working conditions. As a result, given their higher unit production costs, newly created, more durable materials (such fluoro-polymer based compounds) must be moulded at high production rates with low scrap levels. Due to their chemical and physical characteristics, which make them challenging to mould and release, this presents a challenge to the release agent sector.

The demands on part appearance have increased as well. In many cases, parts are used directly from the mould with very little additional polishing. The car industry demands that immediately after delivery, highly visible components like steering wheels or dashboards have strict visual qualities (such as texture, gloss level, and resistance to surface defects).

In recent years, high integrity (semi-solid and squeeze) casting has increased, the complexity of the moulds has increased, cycle times have decreased, and die temperatures have further increased in high-pressure aluminium die casting. To create quality components under the more challenging casting conditions, the release agent must have increased anti-solder and release qualities in addition to better lubrication. This must be accomplished without sacrificing the release agent’s other performance characteristics.

Other industries, including the production of low profile tyres by tyre manufacturers, also benefit from the development of more intricate and sophisticated mould designs. With regard to release ease and rubber flow, these mould designs place higher performance demands on the release agents. It is quite difficult to release these kinds of tyres with ease and meet high aesthetic standards since the post-moulding appearance of tyres is also very crucial.

Due to HSE standards, manufacturing facilities are still required to utilise reduced VOC (volatile organic compound) products. This is crucial for operations that call for a greater level of direct operator participation, such as those in the composites industry. The development of items that are safer to use and more environmentally friendly will continue to receive more attention. This will encourage the development of novel release agents to satisfy these objectives while maintaining the same level of performance as the currently available solutions.