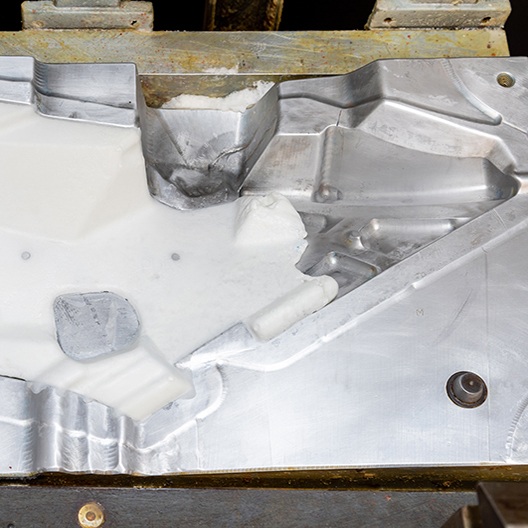

Short shot, incomplete moulded foam part

Description:

Due to insufficient foam flow, a polyurethane foam part is incomplete.

Affected Foam Parts:

Affected are parts made of soft foam, high resilient foam, viscoelastic foam for automotive or furniture industry (headrests, armrests and cushions, as well as pillows and mattresses), acoustic foam, insulation foam and back foam.

What causes it:

If the amount of polyurethane foam injected is too small, or the ventilation of the mould is insufficient, this can result in the mould not being completely filled. Also an incorrect temperature of the mould or the PU system, too fast PU reaction and a wrong poly/iso ratio can cause incomplete moulding of the foam part.

- Too low weight/amount of PU foam injected /poured

- Bad mould ventilation

- Improper mould temperature

- Too fast PU reaction

- Improper PU system temperature

- Wrong Poly/Iso ratio

Solutions:

The monitoring and control of the above factors ensures the production of high quality polyurethane foam parts. To minimize quality problems, ventilation channels, shot quantity and process parameters must be checked accordingly and measures taken if necessary. Adjusting the mould temperature or changing the release agent may also be necessary measures.

- Check the PU machine parameters and PU shot weight

- Check and clean ventilation channels

- Adjust mould temperature

- Change the Release Agent type

- Check PU reaction with cup test

RELATED CASE STUDIES

Chem‑Trend is the global expert in mold release agents, purging compounds, and paper impregnation chemicals, delivering innovative solutions that improve efficiency, reduce waste, and enhance manufacturing performance across diverse industries worldwide.

© 2026 Chem‑Trend L.P. or Chem‑Trend affiliated company. All rights reserved.

Regional websites:

-

Argentina

-

Brasil

(Brazil) -

Canada

-

Česko

(Czech Republic) -

CIS (excluding Russia)

-

Deutschland

(Germany) -

España

(Spain) -

France

-

India

-

Italia

(Italy) -

México

-

România

(Romania) -

Polska

(Poland) -

Türkiye

(Turkey) -

United Kingdom

-

United States

-

Việt Nam

(Vietnam) -

中国

(China) -

한국

(South Korea) -

日本

(Japan)

Notice

You are about to exit this page. You will be redirected to the Chem‑Trend Global website where you’ll find your requested content in English.

Continue