SprayIQ™: A smart innovation that brings application accuracy and significant savings

WHAT WE ACHIEVED.

A global automotive supplier producing high-resiliency seating foam was experiencing an issue with overspray of their release agent. The result: product waste and excess buildup on molds. With the help of SprayIQ™ — an entirely new innovative monitoring device created by Chem-Trend engineers — and a higher-performing release agent, the company was able to achieve a 47% reduction in product use and 50% reduction in scrap rate. This amounted to 22% annual material cost savings. Reduced cleaning due to less mold buildup, lower VOC emissions, and an improvement in overall productivity were also achieved. In the long-term, the company will be able to precisely forecast product consumption for more accurate ordering. Training for the system and its data reporting was provided by Chem-Trend, which helped operators and managers better monitor throughputs for improved application consistency.

HOW WE GOT THERE.

Working closely with the customer to find an ideal solution, together we embarked on an in-depth trial with SprayIQ™. Central to the overspray issue was that individual spray operators were manually turning up levels hoping

to produce better release with the use of more product. Connected to the customer’s existing spray guns and set up within one day, SprayIQ™ was designed to address this challenge with the following features:

- Measures spray application accurately

- Provides immediate feedback to the operator

- Delivers spray application data to process engineers and line supervisors via a mobile device

The release agent in use was also replaced by a more suitable Chem-Trend product specifically designed for high-resiliency foam applications and popular among polyurethane customers.

OUR SOLUTION.

Trial results of SprayIQ™ combined with our high- performing release agent were so positive when used with the customer’s existing equipment, they eventually switched to Chem-Trend’s spray guns for even more added benefits. Paired with a high level of on-site and remote support, the modification prevented operator intervention while still producing optimal release and through-put levels during every shift. Our more effective release agent provided good wetting and spreading, reduction in buildup on the molds, and easy release of parts. And because superior results were achieved with a lower volume of product, the company was able to lower VOCs to create a healthier environment and save money by avoiding emissions fines and permit costs.

DATA INSIGHTS

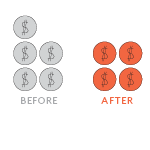

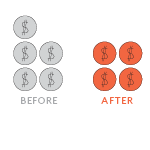

22% Savings on Annual Material Costs

22% Savings on Annual Material Costs 50% Reduction in Total Scrap

50% Reduction in Total Scrap 47% Reduction in Amount of Release Agent Used

47% Reduction in Amount of Release Agent UsedHandprint Impact

At Chem-Trend, we pride ourselves on our long history of sustainability efforts. However, it is our effect on our customers’ processes that provides the greatest impact. It goes beyond our global Footprint; it is our even wider Handprint.

Here, we achieved the following:

- Less product used due to more efficient release agent and better awareness of application amount through SprayIQ™ data reporting

- Less waste and energy use due to reduction of scrap rate and cleaning frequency

- Fewer emissions due to lower volume of release agent used

Materials

Waste

Energy

Emissions