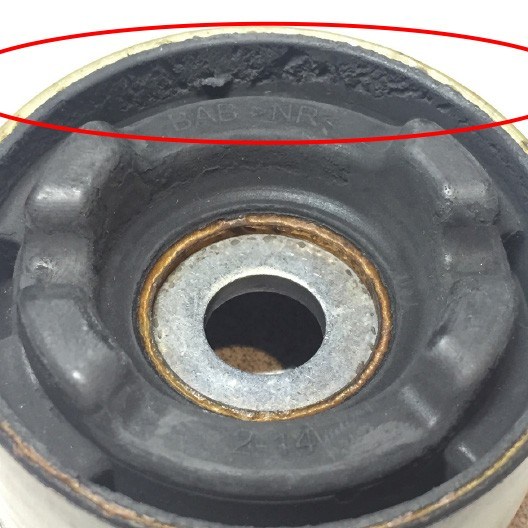

Rubber Chunking

What it is

Rubber chunking occurs when rubber erroneously adheres to the mould as it is being extracted from the mould. This leaves a void in the product being made as well as leaving residue in the mould, affecting both part and process.

What causes it

In a rubber-bonding environment, adhesives give off gasses onto the mould surface, causing the rubber to adhere (bond) to the mould. Chunking typically happens when the rubber-to-rubber bond is weaker than the rubber-to-mould surface bond, which the release agent is there to prevent. Adhesive off-gassing occurs in the closed mould when adhesive on a substrate is heated to the point of becoming a gas. If there is no rubber present in the cavity during this time, the adhesive will then transfer and bond to the mould. This most often happens in an injection moulding or transfer moulding environment.

Solutions

A good release agent will help prevent adhesive transfer to the mould (staining), eliminating chunking issues.

RELATED CASE STUDIES

© 2025 Chem‑Trend L.P. or Chem‑Trend affiliated company. All rights reserved.

Regional websites:

-

Argentina

-

Brasil

(Brazil) -

Canada

-

Česko

(Czech Republic) -

Deutschland

(Germany) -

España

(Spain) -

France

-

India

-

Italia

(Italy) -

México

-

România

(Romania) -

Polska

(Poland) -

United Kingdom

-

United States

-

Việt Nam

(Vietnam) -

CIS

-

中国

(China) -

한국

(South Korea) -

日本

(Japan)

Notice

You are about to exit this page. You will be redirected to the Chem‑Trend Global website where you’ll find your requested content in English.

Continue